The Best Desktop Injection Molding Machines in 2025

May 24, 2025

Leave a message

In the rapidly evolving landscape of modern manufacturing, desktop injection molding machines have emerged as indispensable tools for prototyping, small-batch production, and innovative projects. Whether you're a hobbyist, entrepreneur, or researcher, choosing the right machine can significantly impact your workflow. This guide explores the best desktop injection molding machines on the market, highlighting their features, applications, and why they stand out in 2025.

Key Trends in Desktop Injection Molding

Before diving into our top recommendations, let's examine the latest industry trends shaping the market:

Compact Design & Portability: Machines are becoming smaller without compromising performance, ideal for workshops, labs, and home use.

Material Versatility: Support for diverse materials like ABS, PLA, TPE, and even metal-infused filaments expands creative possibilities.

Smart Integration: Industrial IoT (IIoT) features, such as real-time performance monitoring and remote diagnostics, are gaining traction.

Cost-Effectiveness: Affordable solutions for startups and hobbyists, with entry-level models offering professional-grade results.

What is Injection Molding?

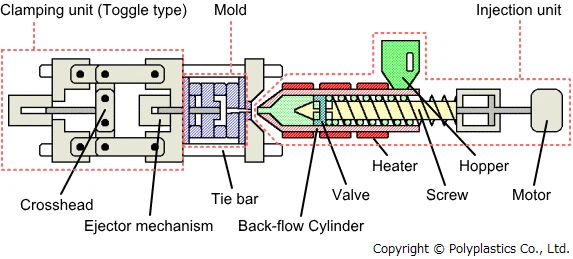

Injection molding involves heating plastic to molten state, extruding it into a mold via a piston (plunger method), and cooling it to form parts.

Key factors include:

Temperature: Must match material's melting point to avoid defects or degradation.

Injection Pressure & Clamping Force: Higher pressure ensures filling complex molds; clamping force prevents mold separation for larger parts.

Shot Size: Desktop machines typically handle ≤50g of plastic, requiring shot size to be 1.5x part size for efficient heating and air escape.

Usability: Prioritize build quality and safety features (e.g., leak prevention). Automatic ejection aids continuous production but adds cost.

When Does Desktop Injection Molding Make Sense?

Faster Than 3D Printing: For small-to-medium batches (hundreds/thousands of parts), ideal for prototype validation before mass production.

Material Advantages: Processes cheap, high-performance materials (PP, PS, TPU, ABS, PLA) with stronger, more consistent results than 3D printing (no layer adhesion issues).

Synergy with 3D Printing

3D-Printed Molds: Resin printers (e.g., Formlabs) produce low-cost, temperature-resistant molds (e.g., High Temp resin) for low-volume use, replacing expensive CNC machining for prototyping.

Limitations: 3D-printed molds lack the surface finish and durability of metal (aluminum/steel), so CNC machines still aid precision for long-term use.

Bottom Line: Desktop injection molding excels in speed, material range, and part strength for small batches, often paired with 3D printing for affordable prototyping workflows.

Top 5 Desktop Injection Molding Machines for 2025

I. Corporate Comprehensive Strength

Shaoxing Xinshan Technology Co., Ltd. was established in 2009. With 14 years of focus on precision manufacturing, it has built an integrated desktop manufacturing ecosystem covering 3D printing, 5-axis CNC machining, 3D scanning, and injection molding.

R&D and Innovation: Equipped with an independent R&D center, the company holds over 20 patents. Core products are certified by CE and FCC, and it collaborates with universities to transform cutting-edge technologies (e.g., AI intelligent temperature control, lightweight structural design) into product competitiveness.

Global Layout: Its sales network covers 19 countries and regions, with 48 branches enabling 24-hour localized response. Relying on 300 global distributors, it provides one-stop solutions for equipment and materials across industries such as education, healthcare, automotive, and aerospace.

Certifications and Clients: Certified to ISO 9001, medical-grade equipment meets FDA standards. Serving 532 enterprises with an 85% repurchase rate, it has provided micro-injection solutions for German automotive parts manufacturers and customized high-precision denture mold systems for U.S. dental clinics.

2. Strength in Desktop Injection Molding Machines

Designed for laboratory R&D, small-batch production, and customized manufacturing, it addresses the pain points of traditional injection molding machines (large size, high cost).

Structural Advantages: Occupies <1㎡ floor space, plug-and-play; modular design enables mold change within 10 minutes, supporting multi-category production switching.

Performance Parameters: Clamping force ranges from 5-30 tons, equipped with high-resolution servo motors and closed-loop control, achieving repeat positioning accuracy of ±0.02mm; temperature control accuracy of ±1℃, compatible with 20+ materials (ABS, nylon, TPE, medical-grade resins, etc.).

Intelligence and Usability: Features a 7-inch touchscreen HMI with built-in process parameter libraries; supports USB/Ethernet data transmission and is compatible with third-party CAD software (e.g., SolidWorks) for fully digitalized "design-modeling-injection" workflows.

Energy Efficiency and Reliability: All-electric servo drive reduces energy consumption by 50%, compliant with RoHS standards; key components (screws, barrels) use aviation-grade stainless steel, with a service life exceeding 10 years and 30% lower maintenance costs.

Industry Solutions:

Healthcare: Provides GMP-compliant models for cleanrooms, supporting precision mold development for syringe components and dental implant models.

Education & Makers: Offers teaching kits (including basic molds and material packs), adopted by 50+ global university laboratories for STEAM curriculum implementation.

Automotive Electronics: Customizes micro-injection solutions for new energy vehicle manufacturers, producing precision parts (connectors, sensor housings) with a yield rate of 99.2%.

Contact Information

Tel: +86-13305858081

Email: xslightings@xslightings.com

Website: www.xslightings.com

2. Yizumi UN Series All-Electric Desktop Machine

Innovation at Its Core:

Yizumi's UN-30AE stands out with its all-electric design, delivering silent operation (≤65dB) and European CE certification. Its patented fast mold-change technology reduces downtime to just 5 minutes, boosting productivity for flexible manufacturing.

Key Features:

Specialized for flexible materials (TPE, silicone), ideal for medical tubing and automotive seals.

IIoT connectivity for real-time pressure/temperature monitoring and MES system integration.

3. LK Group Pioneer 20T

Micro-Molding Excellence:

Designed for ultra-precision, the Pioneer 20T from LK Group excels in producing tiny components (e.g., watch gears, micro-electronic parts) with a repeatability accuracy of ±0.01mm.

Key Features:

Energy-saving servo-electric hybrid system (40% lower energy use).

Custom solutions for automotive electronics and Swiss watchmakers, proven in high-precision industries.

4. Botou Intelligent BM Series Two-Platen Desktop Machine

Space-Saving Innovation:

Botou's BM-25 two-platen design reduces floor space by 30%, making it a top choice for labs and startups. Its open-source API allows users to customize parameters and integrate with third-party software.

Key Features:

Educational partnerships with Tsinghua University, offering mold design software bundles.

Ideal for DIY projects and research, supporting rapid prototyping with PLA and PETG.

5. Prusa Research Injection Molding Kit (for 3D Printers)

The Affordable DIY Solution:

Prusa's ecosystem expands into injection molding with a plug-and-play kit for its i3 MK4 3D printer. This budget-friendly option ($2,000+) enables users to switch between 3D printing and molding, perfect for hobbyists and prototyping.

Key Features:

Community-driven design with shared mold files on PrusaPrinters.org.

Supports low-pressure molding for PLA and flexible filaments, ideal for creative projects.

How to Choose the Right Desktop Injection Molding Machine

When selecting a machine, consider these factors:

Application: Prototyping, small-batch production, or specialized use (e.g., medical, automotive)?

Material Needs: Do you require support for advanced materials like metal composites or food-grade plastics?

Budget: Entry-level kits (under $3,000) vs. professional machines ($10,000+).

Space Constraints: Compact designs (e.g., Botou's two-platen) vs. standard setups.

Conclusion

Desktop injection molding machines have democratized manufacturing, putting professional-grade capabilities within reach of creators, engineers, and businesses of all sizes.