pocket nc 5 axis

Desktop NC is 5 axis digital machine tool. Controlled by Windows system, use CAD or CAM to mill. Desktop NC support G code control as well. As pocket size, five axis motor main axis have speed 0-24000rpm, enough for professional designer basic application. Equipment size:600x400x510mm

bed dimension:φ100mm

Maximum payloadof the work table:5kg

speed 0-24000rpm

Windows System Control

Support G code control

CAD or CAM milling

Description

Technical Parameters

Products Description

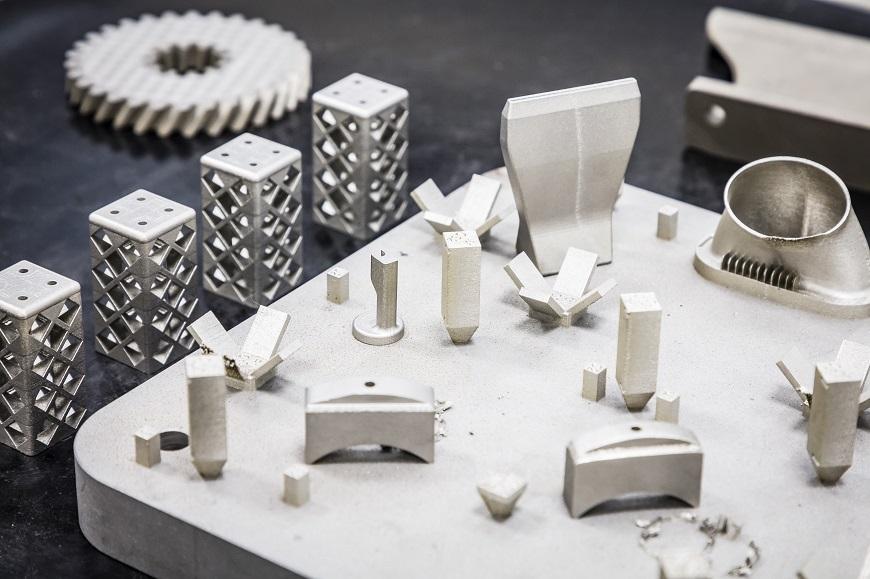

The Pocket NC 5-Axis CNC machine is an advanced desktop machining center designed for precision prototyping and small batch production. Equipped with the upgraded No.57 servo motor, this compact and versatile machine offers a movement speed of up to 12m/min, significantly outperforming the standard motor's 2.5m/min speed. The servo motor operates quietly, with high responsiveness and excellent positioning accuracy, ensuring smooth operation and minimizing errors. The machine is perfect for applications in education, R&D, and precision manufacturing, capable of machining a wide range of materials including aluminum, wood, and plastics. Its robust structure and professional-grade CNC system provide stability, while compatibility with popular CAD/CAM software ensures seamless integration from design to final product. The Pocket NC 5-Axis CNC machine is ideal for teaching, training, and the efficient production of complex parts, offering high-precision capabilities for intricate geometries and fine details.

Five-axis simultaneous machining: supports five-axis simultaneous machining, can handle complex geometric shapes and details, and improve machining accuracy and efficiency.

Compact design: The small desktop structure is suitable for working environments with limited space, especially for laboratories, educational institutions and small-scale production.

High precision: Provides extremely high machining accuracy, ensures the precision of parts machining, and meets strict industrial standards.

Wide material adaptability: Able to process a variety of materials, such as aluminum, wood, plastic, etc., to adapt to different production needs and provide flexible application scenarios.

A five-axis CNC test project purchased by the MIT intelligent robot team.

(Several projects designed by the team, including MIT Mini Cheetah: https://www.youtube.com/watch?v=xNeZWP5Mx9shttps://www.youtube.com/watch?v=G6fMV1UPzkg and the fastest Rubik's Cube solution in the worldRobot question: https://www.youtube.com/watch?v=nt00QzKuNVY uses Pocket NC machines to manufacture parts for similar robot projects.)

Tech Specs

| Packing Size | W800xD600xH800mm | Packing weight | 100-120kg |

| Equipment size | W600xD400x H510mm | weight of equipment | Net weight of 45kg,with sheet metal of 75kg |

| Bed Dimension | φ100mm | Maximum payload of the work table |

5kg |

| XYZ effective travel | X160xY200xZ130mm | AC effective travel | A:-30-120°,C 360° |

| Three axis processing range | X160xY200xZ125mm | Five axisprocessing range | Cylinder:φ 150 H105mm,φ 100 H120mm,cube W125D 125 H110mm |

| Three-axis processing accuracy | Linear axis parallelism & vertical degree of 0.03mm, Travel range is 0.02mm |

Five axis processing accuracy | Linear axis parallelism &vertical degree of 0.05mm, Fve-axis spatial accuracy of<0.05mm |

| XYZ Ball wire rod | X&Z:1204C7,Y:1604 C7,up gradable C5 | AC axis |

1:80 20 Harmonic reducer return<1' |

| The XYZ linear guide rail | X&Z Hiwin MGN12 Y:Hiwin MGN15 | body frame | 6061T6 aviation aluminum+stressed component adjustment of 45 steel |

| Processing speed | 4000mm/min vary by material | ||

| principal axis | φ65mm 800W Water-cooled electric spindle at 24,000r /min |

protect | Organ is dust-proof +oil seal is waterproof and dustproof |

| Tool diameter& length | ER11.0-8mm,≤75mm | Part fixtures | Steel fixture with reserved hole position Can add er50 clip holder,63,80 card |

| work material | Metal:aluminum alloy.copper alloy,gold alloy,silveralloy.*steel,*titanium alloy | / | Non-metat plastic,wood,wax,jade,glass etc |

Shipping List

| Order Number | Type | Name | Explain | Quantity |

| 7 | Equipment | Main Engine | Naked machine does not contain sheet metal |

1 |

| 2 | Material Fixtures | Type A: self-centering platform pliers |

8-55mm square ping | 1 |

| 3 | Knife Fixture | ERlI clamp cylinder | ER11-4&ER11-6 | 1 |

| 4 | Cutter | Sharp knife,vertical miling cutter,ball knife |

0.2mm sharp knife (for carving)10 2,4,6mm vertical milling cutter 2, R ball knife 2 |

18 |

| 5 | Electrical | power box | Motor control frequengy converter | 1 |

| 6 | power line | Total power supply for equipment | 1 | |

| 7 | USB data wire | Connect the computer to the host machine | 1 | |

| 8 | Electronichand wheel | Operation shaft movement | 1 | |

| 9 | Tool | 1 set of inner agon wrench | 1.5-109PCS | 1 |

| 10 | A set of spindle wrench | 14 &17mm open-wrench | 1 | |

| 1 | Material | Generation wood 4 pieces | Practice with | 1 |

Options and upgrades

| Order Number | Type | Name | Explain | Quantity |

| 1 | Transmission | Domestic grinding of C5 silk rod | 1204 &1604 | 3 |

| 2 | Prindpal axis | 40000r pm | Also power 800W 65mm diameter | 1 |

| 3 | Knife Fixture | Spindle ER11 clip cartridge | 2~8mm full set | 10 |

| 4 | Square Material Fixture | A self-centering clamp reverse clamp | 50-75mm clamp range | 1 |

| 5 | B increase self-centering pliers | 0-100 mm clamp range | 1 | |

| 6 | Stick fixture | Hand tight 80 clamp (four paws) |

Occupying height 48mm travel,can hold the rod material &square material |

1 |

| 7 | Metalworking 80 chuck (three caws) |

The height of 66mm travel,the centricity is better than the four daws |

1 | |

| 8 | ER40 splint | High grip concentricity,used with ER40 | 1 | |

| / | (ER50,ER40 two optional one) | Cartridge (Clamp-holding Φ 4to 30 mm) | ||

| 9 | One set of ER40 clips | 6.8.10.12.15.18.20.25.28.30mm Clamp cylinder (corresponding to same diameter) |

10 | |

| 10 | ER50 splint | Use with ER50 cartridge (damp Φ 4-36mm) | 1 | |

| 11 | ER50 cartridge optional model | Within 4-36 mm of optional size,70 yuan each | 1 |

pocket nc 5 axis Manufacturer

why choose our products

Space saving: The compact desktop design makes the Pocket NC 5-axis CNC machine very suitable for small workshops and limited space working environments, providing efficient processing solutions without occupying a large production area.

Excellent processing accuracy: Through advanced five-axis synchronous processing technology, it can efficiently process complex parts and delicate geometric shapes, ensuring high precision and consistency of each processed part, and improving product quality.

Multi-material compatibility: Supports the processing of a variety of materials, including metal, plastic and wood, adapts to various industrial needs, has greater flexibility, and meets the processing requirements of different projects.

Easy to operate and integrate: Compatible with mainstream CAD/CAM software, simplifies the workflow from design to processing, has a user-friendly interface, is simple and easy to learn, reduces dependence on technicians, and is suitable for users of different levels.

Application of procket nc cnc

Dental field: used for precision machining of dental restorations, denture customization and dental tools. Its high precision and five-axis simultaneous machining capabilities are very suitable for complex dental models and equipment production.

Education and training: In disciplines such as mechanical engineering, design and manufacturing, it is used as a teaching tool to help students learn five-axis machining technology and perform practical operations.

R&D and prototyping: widely used in product prototyping and small-batch production, helping R&D teams achieve a seamless transition from design to finished products.

Precision manufacturing: suitable for the production of aerospace, automotive parts and other precision mechanical parts, capable of processing a variety of materials to meet high-precision machining needs.

Competitive advantage

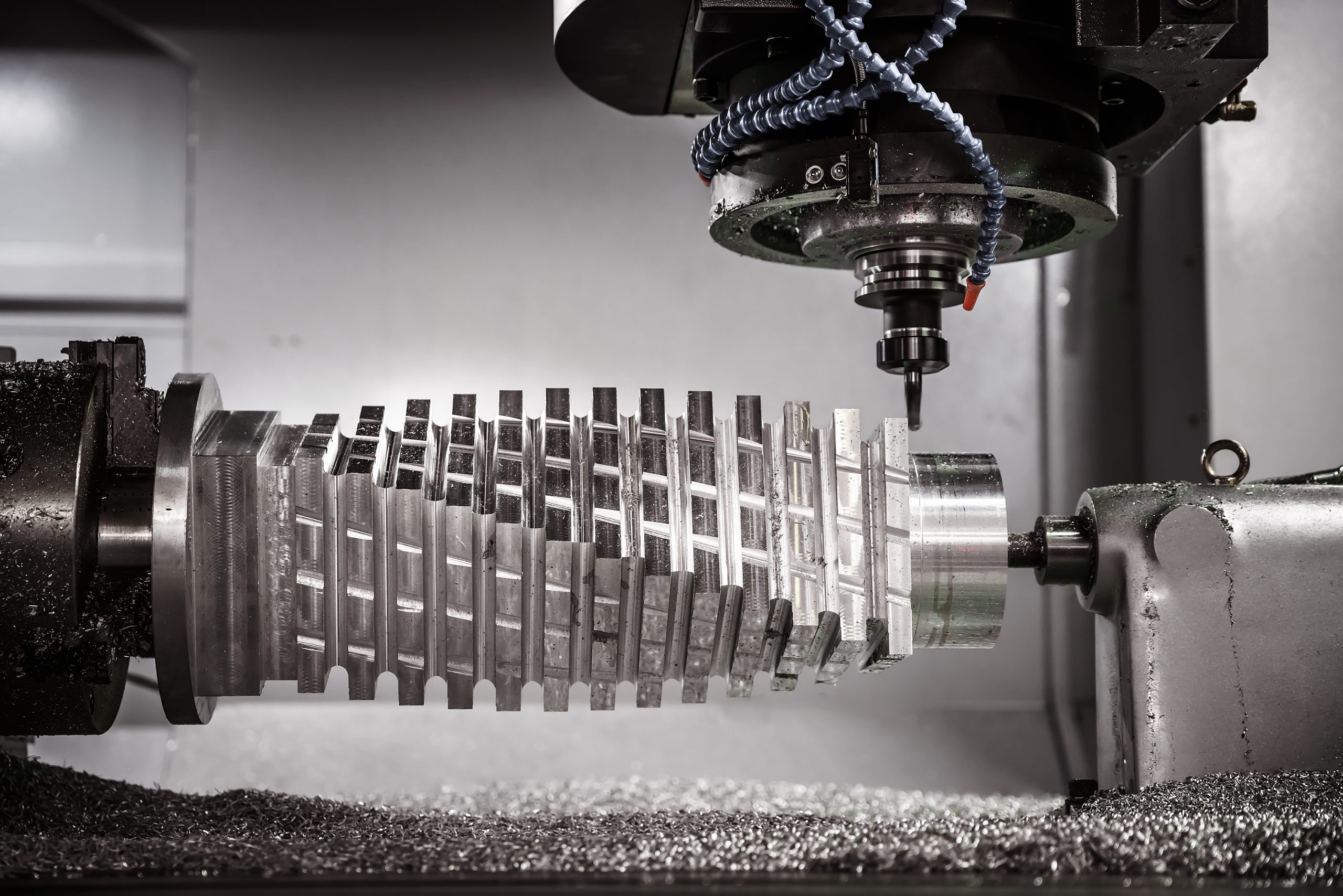

The Pocket NC 5-Axis CNC machine tool performs precision machining through its five-axis synchronous control system. Its working principle mainly includes the following steps:

Computer Numerical Control (CNC) Control

Users design the 3D model of the workpiece through CAD/CAM software and convert it into numerical control code (G-code). These codes are transmitted to the CNC control system to guide the machine to accurately perform processing tasks.

01

Five-axis synchronous processing

The machine is equipped with three linear motion axes (X, Y, and Z) and two rotation axes (A and B axes). The simultaneous movement of these five axes can achieve complex 3D processing. Through the five-axis linkage, the workpiece can be cut at different angles and directions, ensuring high-precision processing of complex geometric shapes and details.

02

High-precision positioning

The machine uses a precision No.57 servo motor to provide high-response and high-precision motion control. The servo motor has low noise, high reaction speed and excellent positioning accuracy, ensuring stability and accuracy during each processing.

03

Material processing

The machine can process a variety of materials, including aluminum, plastic, wood, etc. According to the characteristics of different materials, adjust the cutting parameters such as speed, feed rate, etc. to ensure the best processing effect.

04

Automated operation

During the machining process, the CNC system continuously monitors and adjusts the machining parameters to ensure the smooth progress of the machining process. It also minimizes manual intervention and improves machining efficiency and accuracy through automated tool path planning and adjustment.

05

![]()

Video: https://youtu.be/TNFE7E83VMU

Contact us : xslightings@xslightings.com

wechat id:13305858081

FAQ

Where are your location to produce 5 axis desktop CNC machines?

Can I use other tooling in 5 axis desktop CNC machine?

How much experience is required to use the 5 axis desktop CNC machine?

How about software is needed?

What power is needed for 5 axis desktop CNC?

What size part can I make with the 5 axis desktop CNC V2?

What materials can I cut with your 5 axis desktop CNC?

Are you going to make a machine with a larger work area?

What should I consider when making a part use 5 axis desktop CNC?

You do not ship to my country, can I still order a 5 axis desktop CNC? What is ex works delivery term?

What are the packaging dimensions of 5 axis desktop CNC?

How should I clean 5 axis desktop CNC?

Does the machine stay over a long period of time?

What kind of maintenance is required?

What are the benefits of 5-axis CNC machining?

Why is it called the 5 axis?

What is the principle of 5 axis CNC machine?

What is 5-axis CNC structure?

What does axis mean in CNC?

What is simultaneous 5 axis machining?

1.Where are your location to produce 5 axis desktop CNC machines?

We design, manufacture, and produce our machines in our workshop in China. The machining is either done here in our workshop or by machinists in our domestic mainland. We source as many parts as possible from Taiwan or Japan. We ship all machines from our workshop here.

2.Can I use other tooling in 5 axis desktop CNC machine?

We offer tooling or you can buy from internet. As long as the shaft of the tool can fit in, you can use it. We offer the sizes ER11: 1/8", 3/16", 5/16", 1/4", 3mm, 4mm, 5mm, and 6mm, and 7mm

3.How much experience is required to use the 5 axis desktop CNC machine?

If you have worked with 3-axis, but not 5-axis machining, there is a learning curve, but you can get started using the machine right away with your 3-axis experience and then move into 5-axis.

If you have CAD experience, but no CAM experience then you may want to buy and download the Autodesk Fusion 360 Ultimate before deciding to purchase the desktop CNC V2.

4.How about software is needed?

We suggest to use Autodesk, as for Fusion 360, it is free for educators/students, hobbyists, and startups and is compatible with Windows and OSx. You may also use whatever CAD/CAM software you would like

5.What power is needed for 5 axis desktop CNC?

Power supply: 90-264 VAC,127-370 VDC,47-63Hz,single phase power,a bit over 3 amps at maximum draw, some time, we will supply proper cord for your country free of charge.

6.What size part can I make with the 5 axis desktop CNC V2?

Effective Machining area is X150mm*Y150mm*Z125mm Rotating for A:±110°,C:360°

7.What materials can I cut with your 5 axis desktop CNC?

Our desktop CNC machine can cut any materials with hardnesses up to that of 4140 steel like plastics, Al alloy, Wood, Copper, Gold, Silver, Wax, etc.. We do not recommend cutting composites, ceramics, or gemstones as the abrasive dust will get into machine's bearings and cause pre-mature wear.

8.Are you going to make a machine with a larger work area?

Yes, we have plan to design and make a new machine with a larger work area, however it is future plan, it will be a couple of years from now.

9.What should I consider when making a part use 5 axis desktop CNC?

Can I fit a spinning tool into this space?

Can I start with a piece of material and carve material away with a tool connected to the 5 axis desktop CNC spindle to end up with the part that I want?

How do I hold this part in the 5 axis desktop CNC mill to machine it?

How do I machine this part in subsequent operations and make it accurately?

10.You do not ship to my country, can I still order a 5 axis desktop CNC? What is ex works delivery term?

Yes, we can use UPS or Fedex to deliver to all around world, only depending on collected ship service.

11.What are the packaging dimensions of 5 axis desktop CNC?

650*400*450mm

12.How should I clean 5 axis desktop CNC?

All of the electronics, motors and bearings on the 5 axis desktop CNC are fairly well covered so debris on top of them should not affect functionality. Clean the machine using a vacuum cleaner with an extension and/or soft brush attachment to get it. We do not recommend using compressed air. Compressed air can force chips into some of the electronics causing shorts.

13.Does the machine stay over a long period of time?

When designing the 5 axis desktop CNC, we did a 500 hour run test under 0% load and re-measured the machine after that time. Everything performed within specification. We also manufacture our own worm gears on a desktop CNC V2 and have run this several hundred hours and the gears are still made within specification.

14.What kind of maintenance is required?

If you will be storing your 5 axis desktop CNC for an extended period of time or corrosion is likely for other reasons, a small amount of light oil may be applied to the lead screws and other steel components in order to prevent rust. Store the 5 axis desktop CNC in a dry location, protect the wires from excessive UV exposure and avoid operating the machine immediately after large temperature changes that could cause condensation build up inside the machine. If possible store the 5 axis desktop CNC in a watertight container or a plastic bag and use desiccant to prevent moisture buildup.

15.What are the benefits of 5-axis CNC machining?

The advantages of 5-axis machines include high precision and accuracy, fast production speeds, fewer machine setups, the ability to produce complex geometries, enhanced surface finishes, and improved drilling processes.

16.Why is it called the 5 axis?

When talking about 5-axis machining, it is a more advanced technology over the traditional 3-axis version that has been utilized for decades. This particular model is able to move in five different directions, allowing machinists to have a desired five-sided approach for a single project.

17.What is the principle of 5 axis CNC machine?

5-axis machining works under the same principles as sculpting. You take a large block of material and remove the excess with a cutting tool, piece by piece, until only the end object is left. This process is subtractive, as opposed to something additive like 3D printing, which adds material to a base

18.What is 5-axis CNC structure?

A 5-axis CNC machine has two extra rotary axes which opens the door to an infinite number of machining possibilities. The types of rotary axis include rotary axes A, B and C which rotates around the X-axis, Y-axis, and Z-axis respectively.

19.What does axis mean in CNC?

A: In a CNC machine, an axis is a direction in which the machine tool can move or rotate. The axes on a CNC machine are used to describe its movement capability, typically in a straight line (linear) or around an axis of rotation.

20.What is simultaneous 5 axis machining?

The Concept of Simultaneous 5-Axis

This machining process involves moving the cutting tool and workpiece utilizing the X, Y, and Z linear axes and rotating two of the three A, B, or C axes simultaneously during a machining operation.

Hot Tags: pocket nc 5 axis, China, suppliers, manufacturers, factory, custom, wholesale

Previous

No InformationSend Inquiry

You Might Also Like